Deterministic Part Identification

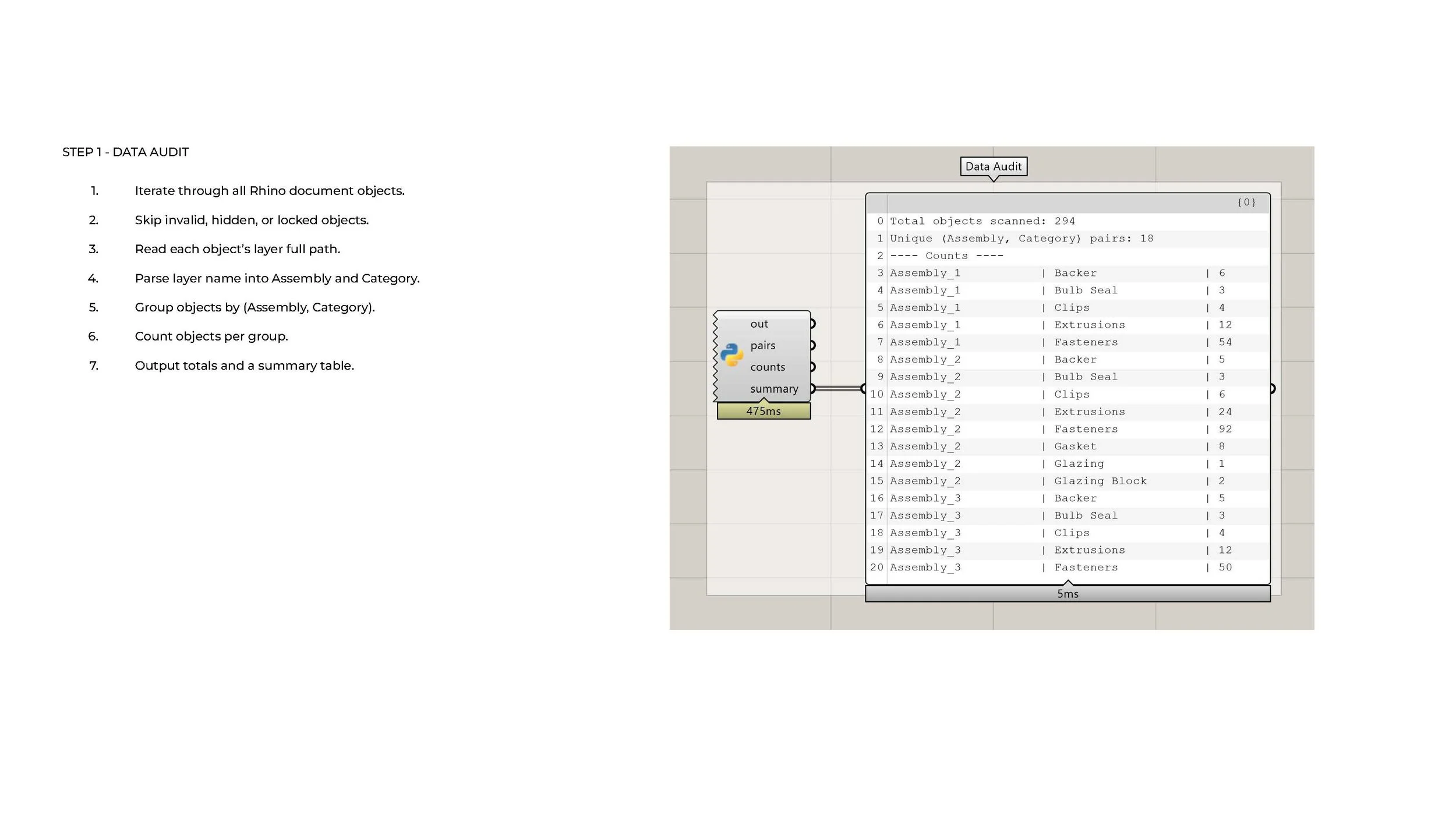

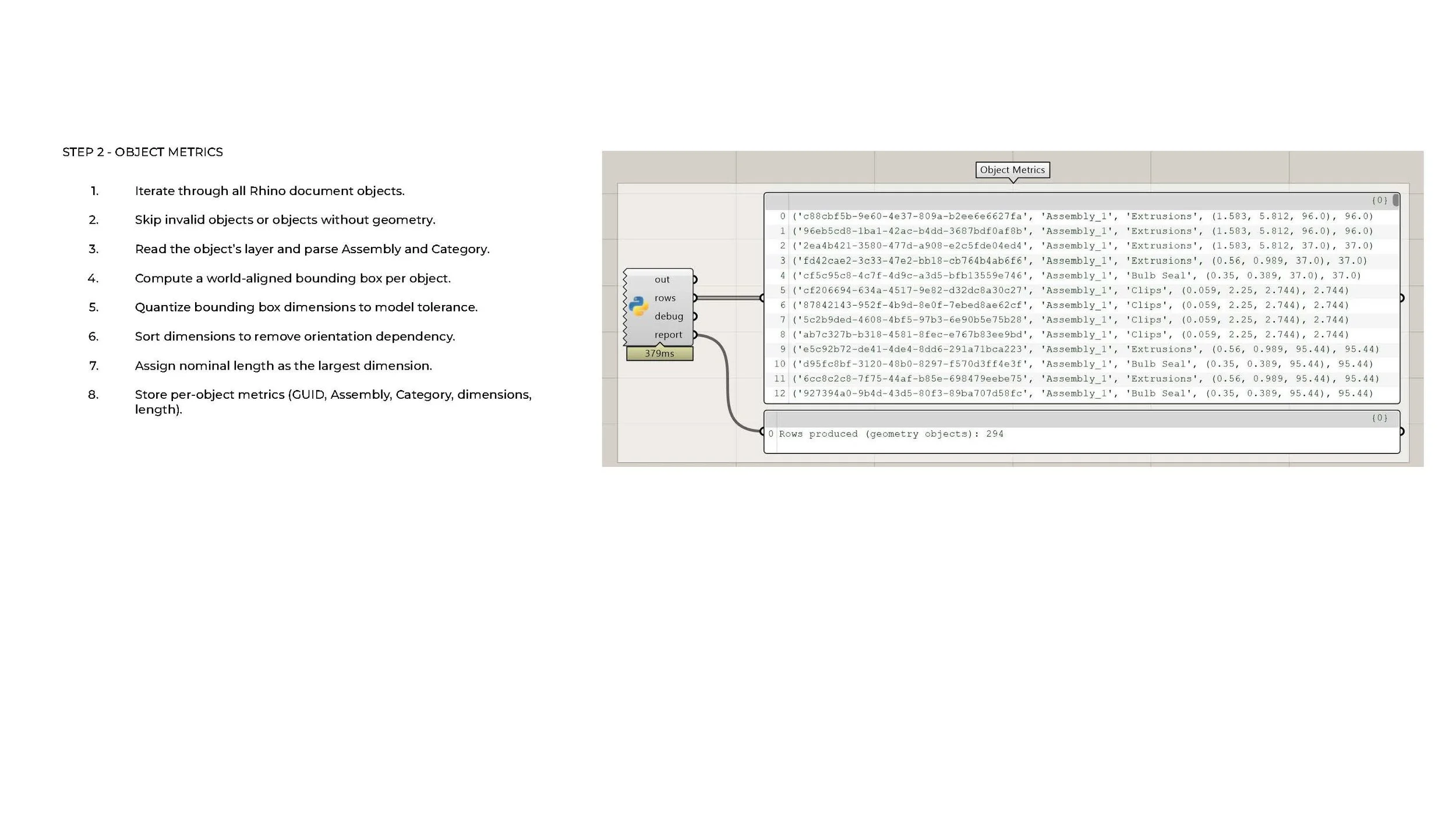

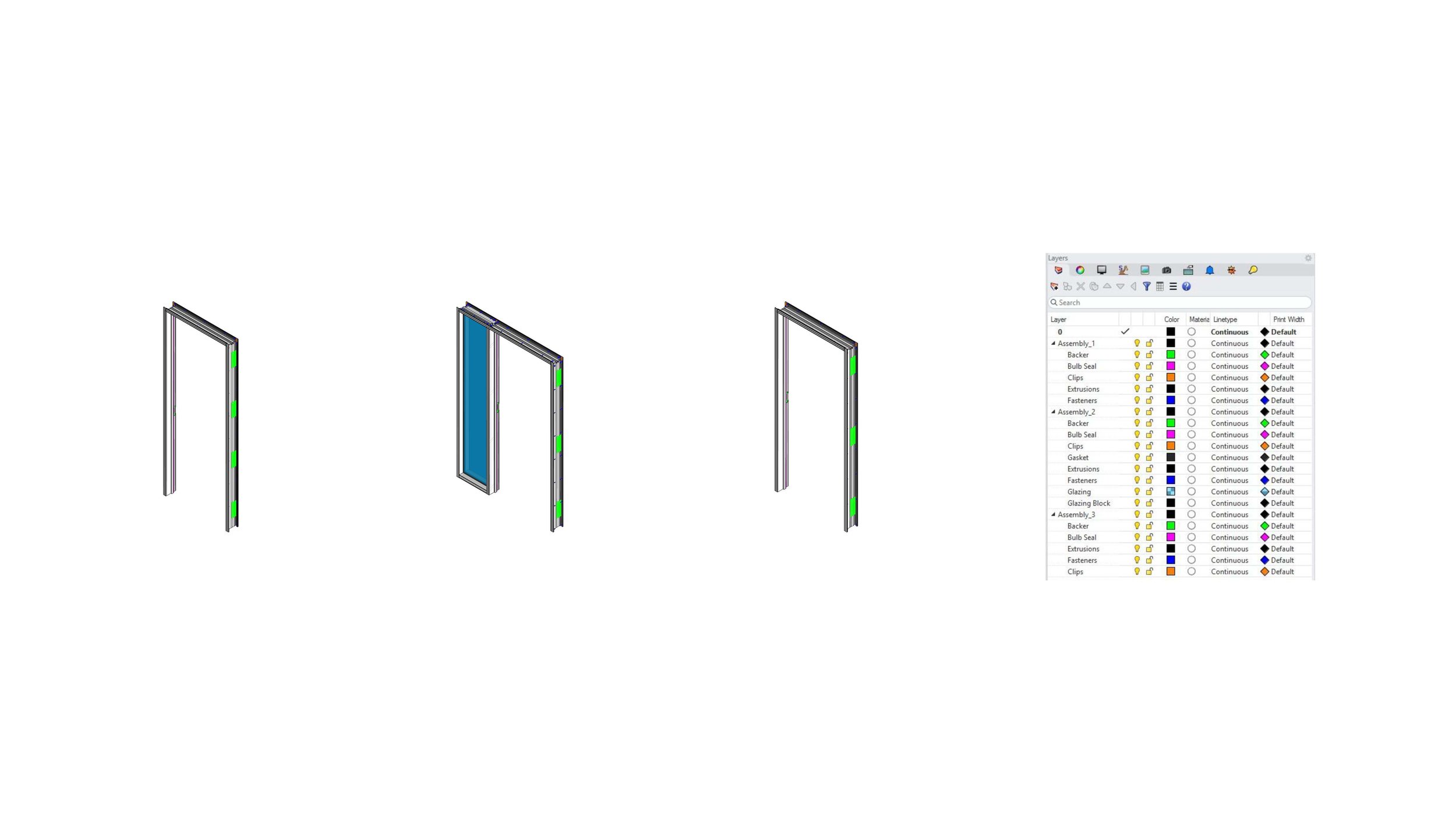

This project develops a geometric canonicalization pipeline for resolving part identity directly from a single assembly file. Rather than relying on external references or manual tagging, the system treats the model as a self-contained source of truth and derives part equivalence through rule-based classification and invariant geometric signatures.

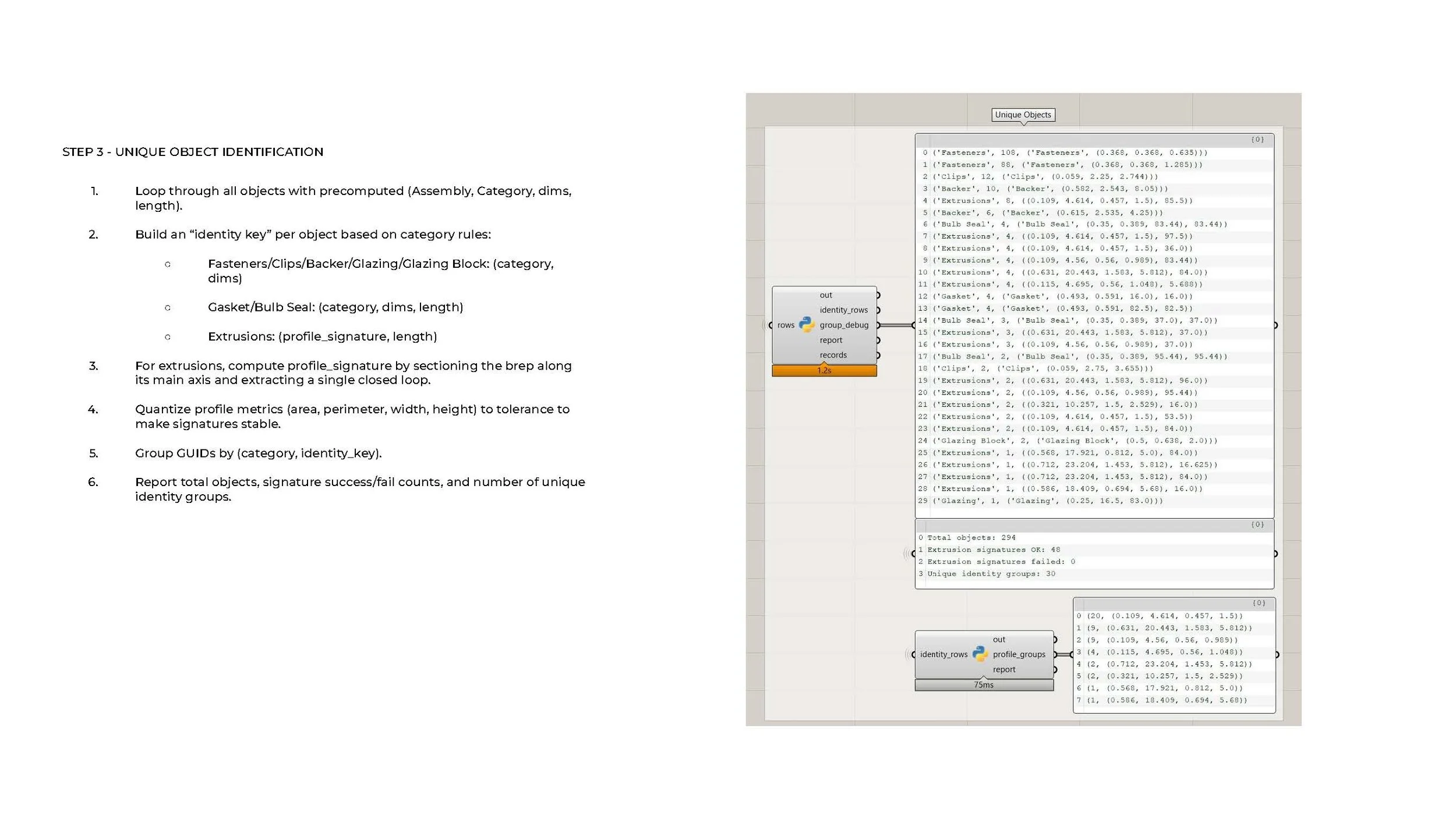

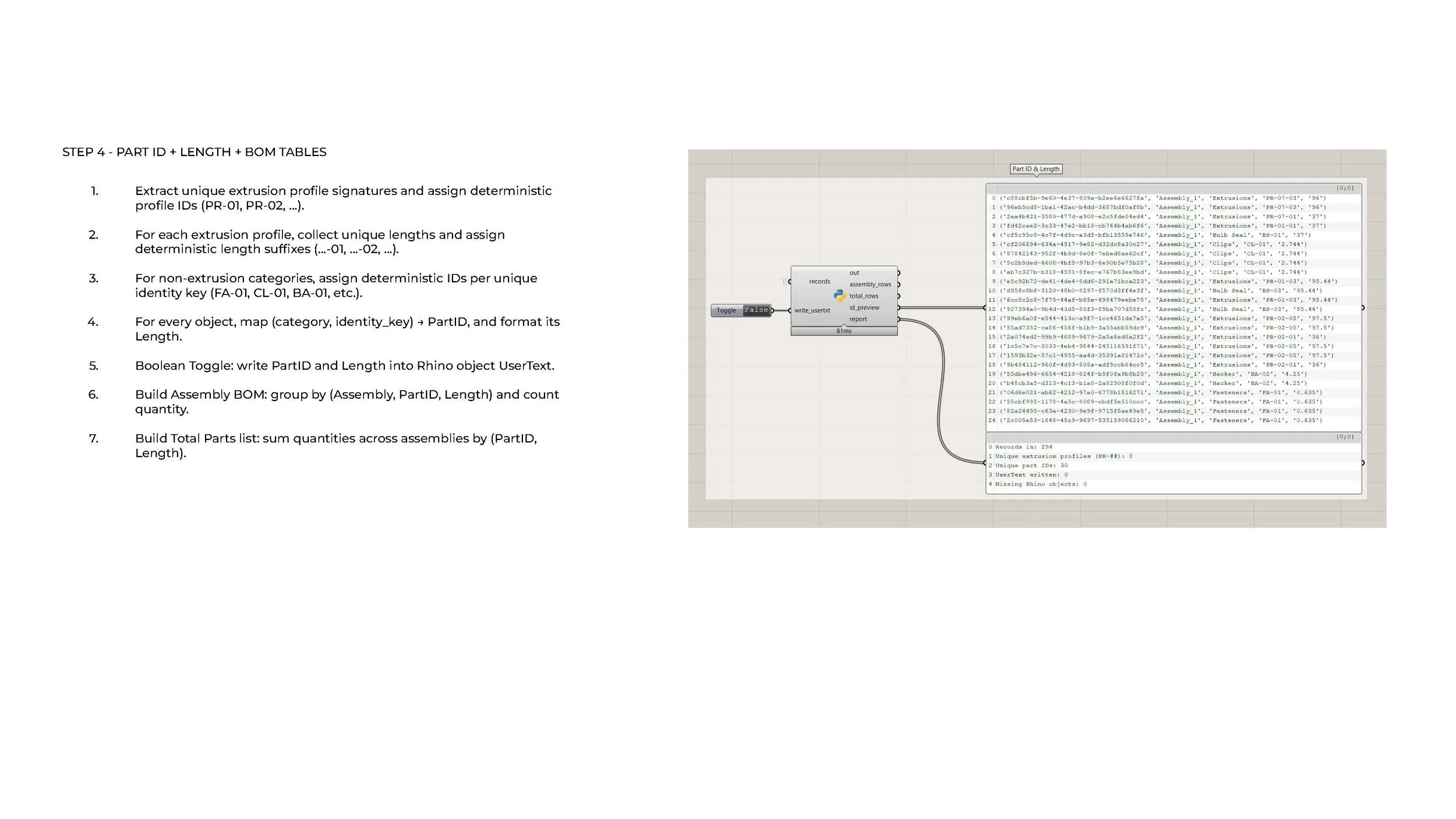

All objects are first audited and grouped by parsed assembly and category metadata. For each instance, orientation-independent bounding box dimensions are computed, quantized to model tolerance, and sorted to eliminate rotational dependency. Category-specific identity keys are then constructed: discrete components are resolved through dimension-based equivalence, while linear extrusions are canonicalized through profile signature extraction. Profiles are generated by sectioning each extrusion along its principal axis, extracting a single closed loop, and stabilizing area, perimeter, width, and height metrics via tolerance-based normalization.

These canonical signatures collapse geometrically equivalent parts into stable identity groups independent of placement, rotation, or duplication. Unique profile IDs and length suffixes are assigned per extrusion family, while non-extrusion components receive identifiers derived from categorical and dimensional equivalence.

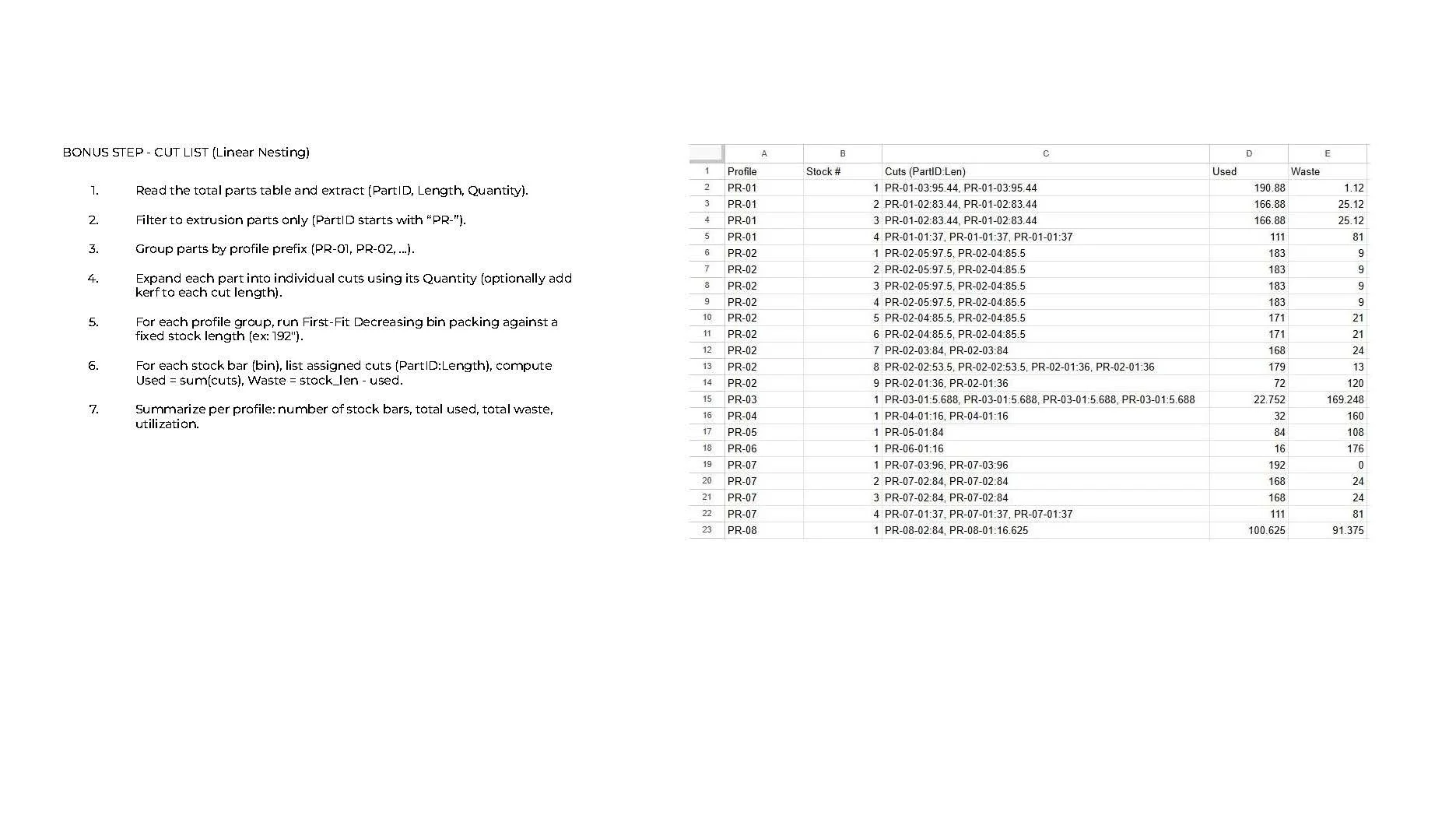

The resolved identity space is compiled into fabrication-ready outputs, including per-assembly BOM tables and a global part inventory. A linear nesting routine applies first-fit decreasing bin packing against fixed stock lengths to evaluate material utilization and waste distribution.

The result is a geometry-driven part identification system that converts unstructured model data into fabrication intelligence through canonicalization, invariant classification, and rule-based compilation.